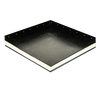

Stall Rubber Matting

A “rubber carpet” was first invented in 1886 by Francis but it was not until 1970 that this was applied to animals when Vilem Stockl filed a patent for a rubber floor mat for animals [1].

There are now numerous stall rubber matting options of various designs and depths available to horse owners. From professional riders and racing yards to private owners and livery yards, stall rubber matting is used extensively throughout the equine industry either as a bedding or a bedding base.

Why use Stall Rubber Matting?

The aim of rubber matting is to provide horses with a non-slip surface and protection from the floor, usually concrete. Depending on the product, stall rubber matting also gives a degree of cushioning.

Sleep requirements of horses

Sleep is one of the most relevant behaviours for biological functioning. It has been studied in many species but only a small number of studies have been conducted in horses. In contrast to most other species, horses can and do sleep standing up, but at some point, all horses must lie down to achieve a full sleep cycle and avoid sleep deprivation

Horses spend most of their time eating, resting, or sleeping and approximately 5-7 hours of each day is committed to resting behaviour, with actual sleep usually occurring after midnight in the dark hours. In a 24-hour period, horses require a minimum of 30 minutes for recumbency to fulfil their rapid eye movement phase (REM) sleep needs. So, its important horses are stalled on a floor which they are comfortable lying on.

Drawbacks of traditional stall rubber matting

Most traditional stall rubber matting consists of individual mats; some are interlocking but all have cracks/gaps between them which allows urine and other liquids to seep underneath and collect under the mats. Urine reacts with bacteria and off gases ammonia, a respiratory irritant to both horses and humans. Even stall rubber matting with draining on the underneath side experience these issues is the slope of the stall floor doesn’t fall towards a drain.

In addition, the cushioning effect of most stall rubber matting is limited so it tends to be used as a bed base and horse owners continue to use large amounts of bedding on top of the rubber matting.

What is the gold standard in stall rubber matting?

ComfortStall is a sealed, padded rubber flooring system made up of three components:

- ComfortStall® Precision Foam™ Proprietary Orthopaedic Padding made from chemically cross-linked PE foam makes it stall and level surface, it is water resistant-hydrophobic and insulates against heat, cold and damp. High durability -tested with 180kg pounded 100,000 times with minimal compaction.

- ComfortStall® IronClad™ TopCover

This component has unmatched longitudinal strength. A single piece sheet (no cracks or joins) with 5 layers: 3x dense vulcanised virgin rubber and 2x tough, tightly-woven polyester nylon means it won’t stretch, wrinkle or bubble. The top cover is impermeable to urine and cleaning products

- HDPE Anchor Resin Strips

- These hold the IronClad™ TopCover in place creating an impermeable barrier. This makes Comfortstall extremely easy to clean, disinfect, swab, mop or hose out.

The Precision Foam™ is put down first, the IronClad™ top cover is then laid on top and lapped up the walls, sealed with the Anchor Strips. This one -piece flooring system means no urine gets underneath the floor so it is much easier to keep the stall clean.

The padding of the Precision Foam™ gives greater flexible support to the horse’s feet or body when lying down and means significantly less bedding can be used. The durable TopCover provides a uniform surface which is high load bearing and can withstand all the wear and tear of a horse on a busy yard or veterinary hospital.

References: